Sunbelt Stud Welding has partnered with Deepwater Corrosion Services, Inc. in the manufacturing of a specially configured non-corrosive, UV resistant and rigid thermoplastic (I-Rod) for the Sunbelt Tubing Spacer (STS).

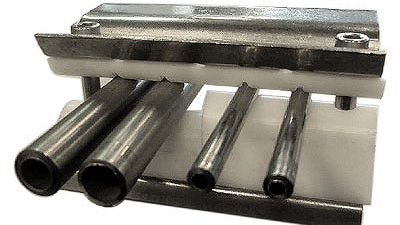

Specially designed notches allow separation between and air flow under the metal tubing, thus ensuring no moisture is collected eliminating possible corrosion or puncture damage caused by shock or vibration.

Sunbelt Tubing Spacer (STS) I-Rod - Technical Specifications.

These notches also ensure any tubing diameter securely stays in place without any metal surface touching the pneumatic tubing.

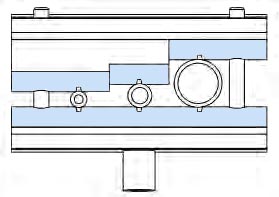

The Sunbelt Multi-Option Hanger (SMO) and Sunbelt Tubing Spacer (STS) can be combined for custom situations depending on your particular needs and application.

Please contact us for technical assistance.

| I-ROD™ STANDARD | |||

|---|---|---|---|

| Property Value | ASTM Test | Metric | Imperial |

| Density, 73°F (23° C) | D792 | 1.41 g/cm | 0.0509lb/in3 |

| Tensile Strength, 73°F (23° C) | D638 | 64.8 MPa | 9,400 psi |

| Tensile Modulus of Elasticity, 73° F (23° C) | D638 | 2.62 GPa | 380 ksi |

| Elongation (at break), 73°F (23°C) | D638 | 30-60% | 30-60% |

| Flexural Modules of Elasticity, 73°F (23°C) | D790 | 2.76 GPa | 400 ksi |

| Flexural Strength, 73°F (23°C) | D790 | 82.7 MPa | 13 ksi |

| Compressive Strength, 10% def, 73°F (23°C) | D695 | 103 MPa | 15 ksi |

| Coefficient of Friction (dry vs. steel) | N/A QTM 55007 | .25 | 0.25 |

| IZOD Impact (notched), 73°F (23°C) | D256 | .534 J/cm | 1 ft-lb/in notch |

| Hardness, Rockwell, 73°F (23°C) M/R | D785 | 88/120 | 88/120 |

| Maximum Service Temperature | (Long Term) | 83°C | 181°F |

| Deformation Under Load | D621 | 1.0% | 1.0% |

| Melting Point | D3418 | 168°C | 329°F |

| Coefficient of Linear Expansion | E831 | 97.2 um/m/°C | 54uin/in/°F |

| Heat Deflection Temperature, 265 psi | D648 | 220°F | 220°F |

| Flammability Rating | VL94 | HB | HB |

| Dielectric Strength, Short Term | D149 | 420 V/mil | 420 V/mil |